Shengzhou Tianyi Electric Appliance Co., Ltd.

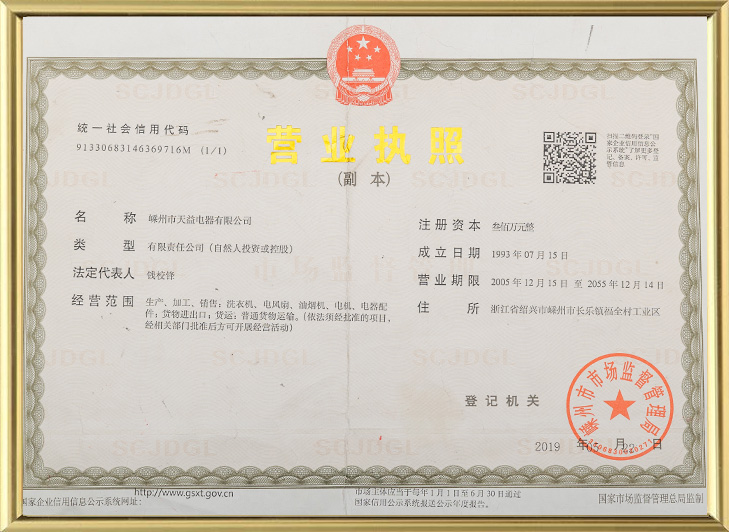

Shengzhou Tianyi Electric Appliance Co., Ltd. was established in 1993 and has been professionally engaged in researching, developing and selling household electrical motors for over 30 years. Tianyi Electric Appliance is

China Ducted Centrifugal Fan Motor Manufacturers and

Custom Ducted Centrifugal Fan Motor Factory .Our company offers services covering design and development to production and assembly. We provide professional solutions to customers's motor problems.

Our factory is located in Shengzhou city which is famous for the production base of motors with complete industrial chains. The city enjoys convenient transportation: east from Ningbo about 100 kilometers, west from YiWu about 60 kilometers, north from Hangzhou about 120 kilometers.

With about 200 staff now, more than 50 personnel are of intermediate titles in management and research and development. Owning fixed assets of RMB 100 million, the factory covers an area of 25,000 square meters, with a building area of 20,000 square meters. Besides, Shengzhou Yijin Trading Co., Ltd. and Shengzhou Dinghui Trading Co., LTD are the two subsidiary companies. At present, The main products of our company include household washing machine motors, household air-conditioner motors, range hood motors, fan motors ventilator motors, etc. The annual production capacity of the factory is more than 10 million motors, and we keep a good relationship with some famous enterprises such as ZhejiangXiabao, KoreaElectric Groupp, Artel Group, SUNG HWA TECH.Co., Ltd. Kumkanggreenfan Co., Ltd., etc.

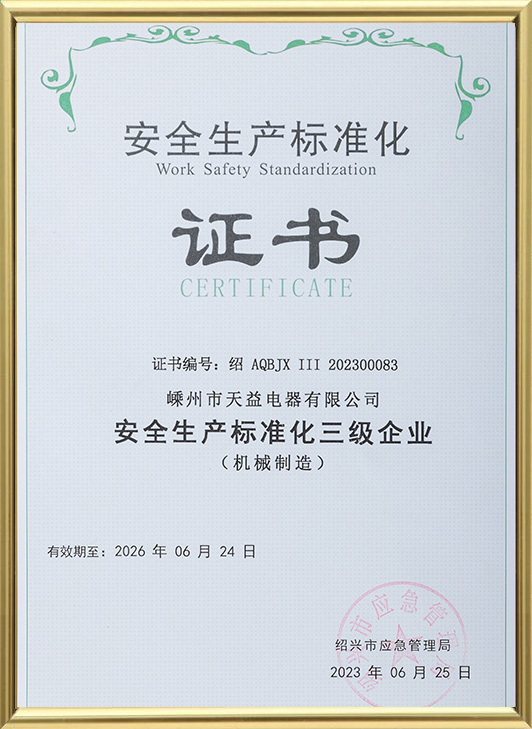

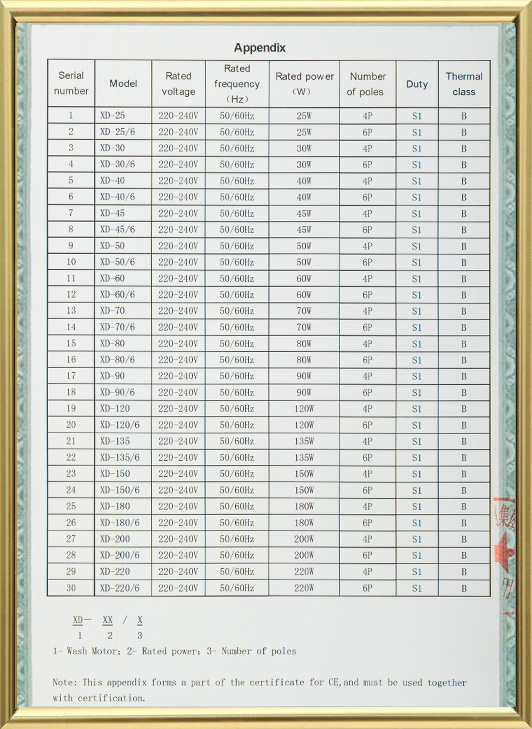

Our company has passed the ISO9001 quality management system and obtained product certifications like CCC and CE.

Shengzhou Tianyi Motor will devote itself to Research Development, and innovation, and we will try our best to provide the best products and solutions for customers with the best service.

In 2023, 12 million household motors were produced, and the total number of washing machine motors was 8 million, range hood motors 1.5 million, fan motors 1 million, ventilator motors 1 million, and on and electric motaccessoriesory half a million.

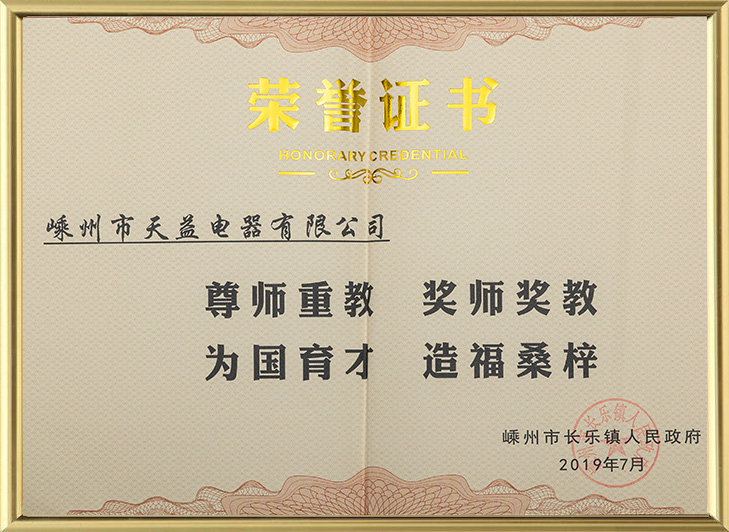

Enterprise honor

In several years of research and development, we paid our sweat to a lot of honors, which also confirmed the efforts we made When look forward,

New targets and new challenges are waiting for us, and we are fully prepared!